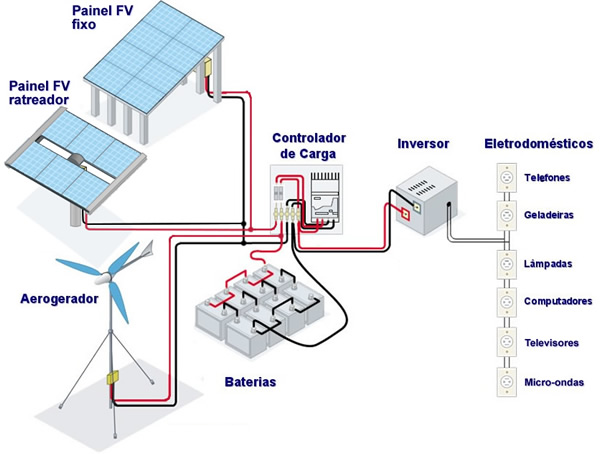

The Efficient Solar House (CSE) is a prefabricated house with its electricity needs fully fulfilled by solar and wind energy sources. The house's power generation system (SGEE) consists of two arrays of polycrystalline silicon (p-Si) photovoltaic modules, being one fixed and one movable with solar tracking system, adding an output of about 1990 watts peak (Wp) and a wind turbine of 1 kW, as shown in Figure 1.

Figure 1 - Configuration of the electrical generation system of the solar house

The electrical system of the Solar House has the following general characteristics:

- Photovoltaic array: 1993 Wp

- Battery Bank: 750Ah/48Vcc (20 units)

- Inverter: 48Vcc/120Vca/60Hz-4kW

- Autonomy: 72 hours

- Projected consumption: 7.4 kWh/day

- Annual average rad.: 4.75 to 5.25 kWh / m2.day (Source: INPE, 2006. Atlas Brasileiro de Energia Solar)

2.1. Fixed panel

Figure 2 - Fixed Photovoltaic Panel on the roof of the Solar House.

The fixed photovoltaic panel installed on the roof of the porch is composed of a total of 32 PV modules (Figure 2). The modules are grouped into connections in a series of four modules each, achieving a voltage of 48 volts DC (direct current). The eight series-groups of four modules are then connected in parallel, as illustrated in Figure 3. The fixed photovoltaic panel has total power of 1450 Wpeak.

Figure 3 - Connection of the modules of fixed photovoltaic panel.

The fixed panel is oriented to the north with an inclination of 22.5° (corresponding to the latitude of the city of Rio de Janeiro).

Figure 4 - Angle of inclination of the photovoltaic panels

2.2. Tracking Panel

Figure 5 - Panel with photovoltaic solar tracking system.

The photovoltaic tracking panel mounted in front of the Solar House has a structure that follows the movement of the sun throughout the day (east - west). It consists of 12 photovoltaic modules connected in groups-series of four modules each (48 Volts DC in each group) associated in parallel. The photovoltaic tracking panel has a total power of 540Wp (Figure 6). The solar tracking structure is a passive system that works based on the movement of a gas between two hollow arms located on opposite sides of the structure.

Figure 6 - Connection of the modules of the PV tracking panel.

Depending on the sun position, one of the arms will be warmer than the other, causing expansion of gas that will move to the less heated arm. The displacement of the gas causes unbalance of weight of the structure, causing it to incline to the side of the heavier arm (the arm less heated by the sun). With the movement of the sun this unbalancing process will occur by gradual displacement of the gas causing the entire structure to follow the sun movement. The motion of the structure is such that the incidence of the sun is always perpendicular to the panel plane, favoring the use of solar energy. The gain of solar radiation of such mobile solar tracking structure is approximately 15-20% compared with the fixed assembly of PV modules.

The voltage generated by the photovoltaic system is 48 volts, direct current (DC). Since all equipment used in the Solar House works in alternating current (AC), we use a voltage inverter that will convert DC to AC.

2.3. Photovoltaic Cells

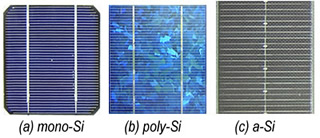

The materials most commonly used in the manufacture of photovoltaic cells are: (a) monocrystalline silicon (mono-Si), (b) polycrystalline silicon (poly-Si) and (c) amorphous silicon (a-Si) (Figure 7). The highest efficiency in converting solar energy into electricity is obtained with monocrystalline silicon cells (around 18%), which are unfortunately the most expensive.The polycrystalline silicon cells present yield by 16% and are cheaper than the previous due to the lower energy required for its manufacture and best use of material.The amorphous silicon cells are cheaper but its yield is still low (around 10%).Photovoltaic cells are connected in series-parallel sets composing photovoltaic modules with different power and voltages.

Figure 7 - Types of commercial photovoltaic cells.

The PV modules are still expensive, making the energy obtained through them, for now, more expensive than that obtained by hydraulic or even thermal sources. However, for regions far from major centers of generation and consumption it is an economical option. For small communities in rural Brazil, for example, it is a viable technical and economical solution. CEPEL, working with the support of PRODEEM, has installed hundreds of systems in this kind of communities with excellent results.

The cost tendency of modules is to decrease, both because of improvements in the manufacturing technology and because of economies of scale by gradual increase of its use.